PRODUCT CATEGORY

-

Experienced R&D team

Bonovo is a fast growing supplier for construction equipment. With more then 20 years technology experience

-

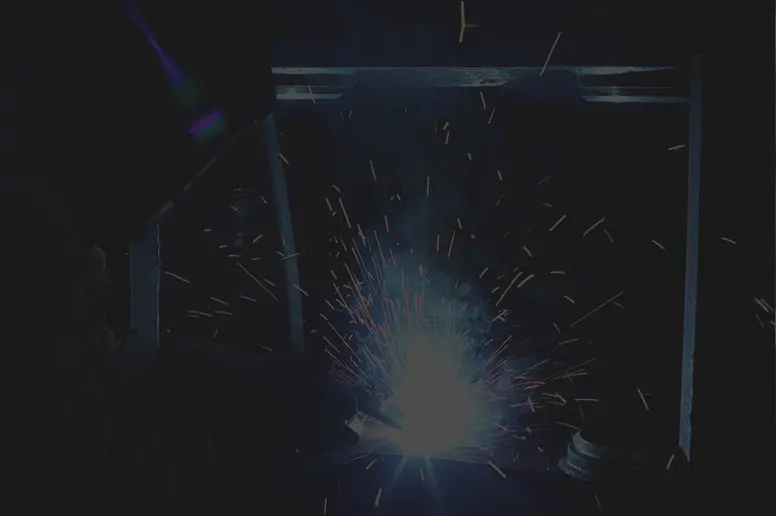

High-skilled workers

Welding is the most important process during bucket making, all the welder in Bonovo are well trained with more than three-year experience in welding.

-

Specialized equipment

All the equipments used in the process of bucket manufacturing are specialized adjusted to meet a high quality level.

ABOUT BONOVO

Choose a professional construction machinery supplier

Xuzhou Bonovo Machinery & Equipment Co., Ltd. is a professional company integrating R&D, manufacturing and sales of construction machinery attachments, GET parts, and undercarriage. From end-users and OEM partners to our dealers, Bonovo has built a reputation for exceptional quality and customer service. We have built solid cooperation with world - renowned dealers as OEM in supporting processing and provided support services for domestic and foreign manufacturers.

-

10000 +

10000 +Customers

-

5000 +

5000 +Our Products

-

50000 m² +

50000 m² +Our Factory

-

100 +

100 +Service Countries