The Ultimate Guide to Excavator Thumbs: Boosting Your Excavator's Versatility - Bonovo

An excavator is a powerhouse on any job site, but its true potential is often unlocked with the right attachment. One of the most transformative additions you can make is an excavator thumb. This comprehensive guide to excavator thumbs will explore everything you need to know about this indispensable tool. We'll delve into what a thumb on an excavator does, the different types available, how they enhance excavator performance, and how to choose the perfect one for your needs. If you're looking to maximize your machine's efficiency and tackle a wider range of tasks, understanding the benefits of an excavator thumb is crucial. This article is worth reading because, as Allen from BONOVO, a factory specializing in excavator attachments, I'll share insights from years of manufacturing experience, helping you make informed decisions.

What Exactly is an Excavator Thumb and Why Do I Need One?

An excavator thumb is a powerful attachment that mounts onto the excavator stick (also known as the dipper arm), working in conjunction with the bucket. Think of it like the thumb on a human hand; it allows the excavator to grip, grasp, and secure objects much more effectively than a bucket alone. This simple yet ingenious attachment transforms your excavator into a multi-functional material handler, greatly expanding the range of various tasks it can perform. Whether you're clearing land, involved in demolition, or managing scrap, an excavator thumb significantly enhances your machine's capabilities.

The primary reason you need an excavator thumb is for improved material handling. While an excavator bucket is excellent for digging and scooping loose materials, it struggles with irregularly shaped objects like logs, rocks, debris, or pipes. Adding a thumb provides the necessary clamping force to hold these items securely against the bucket, preventing them from slipping or falling during movement. This not only increases safety on the job site but also boosts productivity by reducing the number of trips needed to move materials and minimizing spillage. The thumb offers enhanced control, allowing the operator to manipulate objects with greater precision.

As a manufacturer, we at BONOVO have seen countless customers experience a significant upgrade in their excavator's utility after installing an excavator thumb. It's not just an accessory; for many applications, it's a necessity. The ability to pick up and move a wider variety of materials means your excavator becomes a more valuable asset, capable of handling more complex projects without needing additional specialized equipment. This versatility translates directly into cost savings and improved operational efficiency.

How Does an Excavator Thumb Revolutionize an Excavator's Versatility?

The versatility an excavator thumb brings to an excavator cannot be overstated. It essentially gives your machine a hand, allowing it to perform tasks that involve grabbing, holding, and placing materials with a level of control previously unattainable with just a bucket. This newfound maneuverability opens up a world of possibilities. For instance, in construction and demolition projects, an excavator equipped with a thumb attachment can easily sort through debris, separating recyclable materials from waste, or carefully dismantle structures by gripping and removing sections.

This enhanced versatility and efficiency means one excavator can do the work of multiple machines or reduce the need for manual labor. Consider a landscaping project: an excavator with a thumb on an excavator can place large decorative rocks, move and position logs for retaining walls, or clear brush and trees far more effectively. The thumb makes these material handling tasks quicker and safer. The ability to securely grip objects also means less damage to the materials being moved and to the surrounding environment, which is particularly important in sensitive landscape work or utility installation.

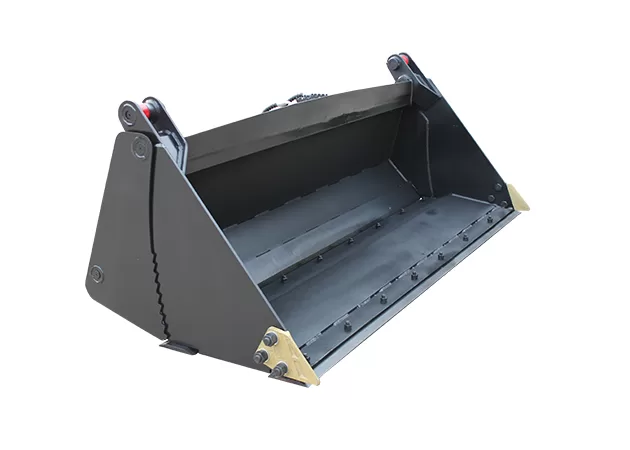

Furthermore, the flexibility and control provided by an excavator thumb can significantly speed up site cleanup. Instead of just scooping, the operator can use the thumb and bucket like a pincer to pick up awkward items. This precision is a game-changer for operators, reducing frustration and cycle times. This attachment makes the excavator a more complete tool, capable of not just standard digging but also intricate material handling, making it indispensable for companies looking to optimize their equipment fleet. For specific needs, you might even consider a robust Excavator Bucket with Thumb for an integrated solution.

What are the Main Types of Excavator Thumbs Available?

When it comes to excavator thumb attachments, there are primarily three main types, each suiting different operational needs and budgets: the manual thumb, the hydraulic thumb, and the progressive link thumb. Understanding the distinctions between these types of excavator thumbs is key to selecting the right one for your excavator.

-

Manual Thumb (Mechanical Thumb):

- Also known as a mechanical thumb or rigid thumb, this is the simplest and most cost-effective type of thumb.

- It's typically pinned to the excavator stick in a fixed position or offers a few manually adjustable positions.

- To reposition a manual thumb, the operator usually needs to get out of the cab and change the pin setting.

- Pros: Lower initial cost, simpler design with fewer moving parts (meaning potentially less maintenance).

- Cons: Less versatile as it requires manual adjustment, which can be time-consuming. The range of motion is limited compared to hydraulic options.

- Best suited for: Operations where the thumb is used for similar-sized objects consistently, or where budget is a primary constraint. Many users opt for our versatile mechanical thumb options for their simplicity and durability.

-

Hydraulic Thumb:

- The hydraulic thumb is powered by the excavator’s hydraulic system.

- It uses a hydraulic cylinder to open and close, allowing the operator to adjust the thumb's position from within the cab.

- Pros: Offers significant greater flexibility and control over material handling. The operator can dynamically adjust the grip on objects of varying sizes and shapes. Hydraulic thumbs offer increased productivity.

- Cons: Higher initial cost than a manual thumb, more complex due to hydraulic components (cylinder, hoses), requiring more maintenance.

- Best suited for: A wide range of applications including demolition, land clearing, scrap handling, and any task requiring frequent adjustments and precise control. A hydraulic thumb is a very popular excavator attachment.

-

Progressive Link Thumb:

- A progressive link thumb is a type of hydraulic thumb that features an extra link in its design.

- This additional linkage provides a wider range of motion – often up to 180 degrees or more – allowing the thumb to curl further and get closer to the excavator’s bucket and excavator stick.

- Pros: Maximum versatility and gripping capability. The progressive link design ensures the thumb maintains consistent pressure throughout its arc, enabling it to handle a very wide variety of object sizes and shapes, even when the bucket is fully curled. These thumbs provide excellent maneuverability.

- Cons: Generally the most expensive option, and the complexity is similar to a standard hydraulic thumb.

- Best suited for: Professionals who need the ultimate in material handling precision and versatility, especially for tasks that involve moving irregularly shaped objects or when working in tight spaces. This type of thumb is often favored in demanding construction and demolition work.

At BONOVO, we manufacture all these types of excavator thumbs, ensuring high-quality materials like wear-resistant steel for maximum durability. The choice between a manual thumb, hydraulic thumb, or progressive link thumb largely depends on the specific needs of your excavator operations and budget.

How Does a Hydraulic Thumb Work on an Excavator?

A hydraulic thumb operates using the excavator’s hydraulic system, which is the same system that powers the boom, arm, and bucket movements. The core components involved are the thumb itself, a hydraulic cylinder, and hydraulic hoses connecting the cylinder to the excavator's hydraulic circuit. When the operator activates the control for the thumb (usually a joystick button or a foot pedal in the cab), hydraulic fluid is directed to the cylinder.

The process is quite straightforward:

- Extension: When hydraulic fluid is pumped into one side of the hydraulic cylinder and the thumb, it pushes the piston rod out. This extension of the rod causes the thumb to pivot away from the excavator stick, opening the grip.

- Retraction: When hydraulic fluid is directed to the other side of the cylinder, the piston rod retracts. This pulls the thumb towards the bucket, closing the grip and allowing it to secure objects.

The beauty of a hydraulic thumb is the precise control it offers. The operator can feather the controls to adjust the thumb's position and gripping force hydraulically, making it possible to handle delicate items as well as heavy, awkward loads. This dynamic adjustment capability is what sets the hydraulic thumb apart from a manual thumb. The thumb can be adjusted on the fly, without the operator needing to leave the cab, significantly boosting operational efficiency and safety. This makes the hydraulic excavator an even more potent tool for various tasks.

Are Excavator Thumbs Compatible with All Excavator Sizes?

Yes, excavator thumbs are designed to be compatible with a wide range of excavator sizes, from compact mini excavator models up to large-scale construction and demolition machines. However, it's crucial to match the thumb attachment to the specific size and weight class of your excavator. An improperly sized thumb can lead to inefficient operation, put undue stress on the excavator’s stick and hydraulic system, or even pose safety risks.

Manufacturers like us at BONOVO offer excavator thumb attachments in various sizes and configurations. When selecting a thumb, factors such as the excavator’s operating weight, the length of its stick, the bucket size, and its hydraulic capacity must be considered. For instance, a thumb designed for a 20-ton excavator would be too heavy and powerful for a 5-ton mini excavator, potentially damaging the smaller machine. Conversely, a thumb for a mini excavator would lack the strength and reach for a larger excavator.

It's always best to consult with the excavator manufacturer's specifications or an experienced attachment supplier to ensure you get the right excavator thumb for your machine. We often assist customers in identifying the perfect fit, considering their specific excavator model and intended applications. Whether you're outfitting a small excavator for landscaping or a large one for heavy demolition, there's a thumb design available to enhance your machine’s capabilities.

What Key Aspects of Thumb Design Should I Consider?

When selecting an excavator thumb, several key aspects of its thumb design significantly impact its performance, durability, and suitability for your excavator and the tasks like those you undertake. Paying attention to these details will ensure you invest in an attachment that meets your expectations.

- Material Quality and Construction: This is paramount for longevity. Look for thumbs made from high-strength, wear-resistant steel (like AR400 or AR500 for the tines). Robust welding and reinforced stress points are also crucial. As a factory, we prioritize using top-grade materials to withstand the tough conditions these excavator thumb attachments face. The durability of the thumb design directly impacts your return on investment.

- Number and Style of Tines: The tine is the "finger" of the thumb. The number and design of tines affect the thumb's ability to grip different materials.

- Fewer, wider tines: Can be good for larger, bulkier objects.

- More, narrower tines: Offer better grip on smaller or irregularly shaped materials and can help sift finer debris.

- Some thumbs feature a solid plate design or a rake-like structure for specific applications. Consider what you'll be handling most often.

- Mounting Style:

- Weld-on thumbs: These are permanently welded to the excavator stick. This offers a very strong and rigid connection. The weld process needs to be done correctly by a qualified professional.

- Pin-on thumbs: These mount using existing or added pins, similar to how a bucket is attached. This can allow for easier removal if the thumb isn't needed for certain jobs, though many operators leave them on.

- Compatibility with Quick Couplers: If your excavator uses a quick coupler system, ensure the thumb design is compatible. Some thumbs are designed to work seamlessly with specific coupler types, allowing for quick changes of the bucket while the thumb remains in place. Using a High-quality mechanical quick coupler from BONOVO can streamline your operations.

- Range of Motion (especially for hydraulic thumbs): For hydraulic thumbs, especially pin-mounted and progressive link models, consider the full range of motion. A wider range allows the thumb to retract further out of the way when not in use and to grip objects closer to the excavator’s bucket. The progressive link design excels here.

- Hydraulic Cylinder Quality (for hydraulic thumbs): The hydraulic cylinder is a critical component. Look for robust seals, a hardened rod, and good protection against damage. The hydraulic cylinder and the thumb must work in harmony.

Considering these design aspects will help you select an excavator thumb that is not only effective but also a long-lasting investment for your excavator.

What Kind of Thumb Work Benefits Most from an Excavator Attachment?

An excavator thumb is a versatile attachment, but its benefits shine brightest in specific types of thumb work where gripping and material handling are key. If your excavator is frequently involved in these tasks, a thumb will dramatically improve productivity and efficiency.

- Land Clearing and Site Preparation: This is a prime application. An excavator with a thumb can easily grab and remove trees, stumps, brush, and rocks. It can stack logs, load green waste into trucks, and generally make the process of clearing land much faster and more organized. The thumb enables the operator to sort materials on-site.

- Demolition: In demolition projects, an excavator thumb is invaluable. It allows the operator to carefully dismantle structures, pick out and sort debris (like concrete, rebar, wood), and load materials into dump trucks or containers. The precision offered by a hydraulic thumb helps in selective demolition and improves safety. The ability to grip large, awkward pieces of debris is crucial for efficient construction and demolition site management.

- Scrap Handling and Recycling: Sorting and moving scrap metal, old appliances, or other recyclable materials is made much easier with an excavator thumb. The thumb makes it easier to pick up and move objects of various shapes and sizes, facilitating efficient loading and processing. This is a key area for material handling tasks.

- Rock and Boulder Placement: For landscapers, construction companies building retaining walls, or in riprap applications, an excavator thumb allows for the precise placement of large rocks and boulders. This is a handling tasks that would be extremely difficult and time-consuming without the secure grip provided by a thumb.

- Pipe Laying and Utility Work: When laying pipes or conduits in a trench, a thumb can securely hold the pipe sections, allowing for easy and precise positioning. This improves safety and accuracy in utility installations.

- Forestry Operations: Beyond land clearing, in active forestry, an excavator with a thumb can assist in loading logs, managing slash, and other material handling needs. Some specialized thumbs are even designed like a rake for forestry floor cleanup.

Essentially, whether you’re dealing with logs, rocks, debris, pipes, or any materials that require a secure hold, an excavator thumb transforms your excavator into a far more capable machine. Thumbs are often the difference between a struggling excavator and an efficient one.

Choosing the Right Excavator Thumb: A Buyer's Guide

Selecting the right excavator thumb involves more than just picking one that fits your excavator. It requires careful consideration of your specific needs, the type of work you do, and your budget. As Allen from BONOVO, I've guided many customers like Mark Thompson through this process, and here are the key factors to weigh:

-

Identify Your Primary Application:

- What kind of material handling will you be doing most often? Heavy demolition? Delicate landscape work? General site cleanup?

- The nature of the work will heavily influence the type of thumb (manual, hydraulic, progressive link) and tine design you need. For heavy, varied work, a hydraulic thumb or progressive link thumb is usually best. For occasional use with consistent material, a manual thumb might suffice.

-

Match the Thumb to Your Excavator:

- Excavator Size and Weight: Ensure the thumb is appropriately sized for your excavator's operating weight and hydraulic capacity. An oversized thumb can strain your machine, while an undersized one won't perform effectively.

- Stick Length and Bucket Size: The thumb needs to be compatible with your excavator’s stick length and work effectively with your existing excavator bucket or any our range of general-duty excavator buckets you might use. The goal is for the thumb and bucket’s teeth to meet or intermesh correctly for optimal grip.

-

Consider the Operator's Needs and Skill Level:

- Hydraulic thumbs offer greater ease of use and precision, which can reduce operator fatigue and improve productivity. They are ideal for operators who need to perform tasks with precision.

- Manual thumbs require the operator to manually adjust the position, which can be less convenient but is simpler to operate for basic tasks.

-

Evaluate Durability and Build Quality:

- Look for high-strength, wear-resistant steel construction.

- Check the quality of welds, pins, and bushings. For hydraulic thumbs, assess the quality of the cylinder and hoses.

- A well-built excavator thumb from a reputable manufacturer will last longer and require less maintenance. This is a key concern for customers like Mark, who value durability.

-

Budget Considerations:

- Manual thumbs are the most affordable upfront.

- Hydraulic thumbs represent a moderate investment.

- Progressive link thumbs are typically the most expensive but offer the highest versatility.

- Balance the initial cost against the long-term benefits of increased efficiency and versatility. Mark Thompson seeks competitive pricing but is quality-sensitive, so finding this balance is crucial.

-

Think About Future Needs:

- Will your scope of work expand? Investing in a more versatile hydraulic thumb now might save you from needing an upgrade later.

By carefully considering these points, you can choose an excavator thumb that will be a valuable attachment for your excavator for years to come. Don't hesitate to contact us for personalized advice.

Installation and Maintenance: Keeping Your Excavator Thumb in Top Shape

Proper installation and regular maintenance are key to ensuring your excavator thumb performs reliably and has a long service life. As a factory, we emphasize these aspects to our customers because they directly impact the attachment's effectiveness and longevity.

Installation:

- Safety First: Always ensure the excavator is on level ground, turned off, and properly secured before beginning any installation work. Release any pressure from the hydraulic system if installing a hydraulic thumb.

- Mounting:

- Weld-on Thumbs: This typically requires professional welding. The excavator stick must be clean and properly prepared. The weld needs to be strong and penetrate correctly to handle the forces involved. Follow the manufacturer's guidelines for placement to ensure proper geometry with the bucket.

- Pin-on Thumbs: These are generally easier to install. Align the thumb's mounting bracket with the pinholes on the excavator stick. Insert the pins and secure them with linchpins or bolts as per the design.

- Hydraulic Connections (for Hydraulic Thumbs):

- Connect the hydraulic hoses from the thumb's cylinder to the auxiliary hydraulic lines on the excavator. Ensure all connections are clean and tight to prevent leaks.

- Route hoses carefully to avoid pinching or abrasion during excavator operation. Use protective sleeves if necessary.

- Testing: After installation, operate the thumb through its full range of motion to check for smooth operation, any binding, or hydraulic leaks. Ensure it closes correctly against the excavator bucket.

Maintenance:

- Daily Checks:

- Visually inspect the thumb for any loose bolts, cracked welds, or signs of damage.

- For hydraulic thumbs, check hydraulic hoses for leaks, cracks, or wear. Check the cylinder seals for any weeping.

- Lubrication: Regularly grease all pivot points (pins and bushings) according to the manufacturer's recommendations. This reduces wear and ensures smooth movement.

- Tightness of Fasteners: Periodically check and tighten any bolts or mounting hardware.

- Tine Condition: Inspect the tines for wear or damage. If they become significantly worn or bent, they may need repair or replacement to maintain optimal grip.

- Hydraulic System (for Hydraulic Thumbs): Maintain the excavator’s hydraulic system by regularly checking fluid levels and changing filters as per the excavator manufacturer's schedule. Clean hydraulic fluid is crucial for the longevity of the hydraulic thumb cylinder.

- Cleaning: Keep the thumb clean, especially around pivot points and hydraulic components, to prevent debris buildup that can cause wear or impede movement.

By following these installation and maintenance practices, you can maximize the performance and lifespan of your excavator thumb attachment, ensuring it remains a productive part of your excavator fleet. If you are looking for other specialized attachments like grab buckets, similar care in installation and maintenance will apply.

Ready to Upgrade Your Excavator? Contact Us!

If this guide to excavator thumbs has shown you the immense potential an excavator thumb can unlock for your machine, or if you have more questions about finding the perfect fit for your excavator, we're here to help. As Allen from BONOVO, my team and I specialize in manufacturing high-quality, durable excavator attachments, including a wide variety of excavator thumbs designed to meet the demanding needs of construction companies, demolition contractors, landscapers, and more, both in the USA and globally.

We understand the challenges faced by business owners and fleet managers like Mark Thompson, who need reliable equipment that offers both quality and competitive pricing. Our B2B model focuses on providing cost-effective solutions that enhance the versatility and efficiency of your excavator fleet. We pride ourselves on clear communication and a deep understanding of excavator operations.

Whether you're interested in a manual thumb, a hydraulic thumb, or a high-performance progressive link thumb, we can guide you through the selection process. We'll consider your specific excavator model, the types of excavator work you do, and your budget to help you find the perfect attachment. Contact us today to discuss your requirements. Let BONOVO be your partner in upgrading your excavator's capabilities and boosting your material handling productivity. We are committed to providing solutions that work hard for you. Contact us – we look forward to hearing from you!

Key Takeaways: The Power of an Excavator Thumb

- Enhanced Versatility: An excavator thumb transforms your excavator into a multi-functional machine capable of gripping and handling a wide variety of materials.

- Increased Productivity: Securely handling irregularly shaped objects means fewer trips, less spillage, and faster cycle times, especially for material handling tasks.

- Types of Thumbs: Choose between manual thumb (mechanical), hydraulic thumb, and progressive link thumb based on your needs for control, versatility, and budget. Hydraulic thumbs offer significant advantages in flexibility and control.

- Proper Sizing is Crucial: Match the thumb to your specific excavator sizes and model to ensure optimal performance and safety.

- Design Matters: Consider material quality, tine design, mounting style, and compatibility with your excavator bucket and quick coupler.

- Key Applications: Thumbs excel in land clearing, demolition, scrap handling, rock placement, and utility work.

- Maintenance is Key: Regular inspection and lubrication will prolong the life of your excavator thumb attachment.

- Expert Advice: Don't hesitate to contact us for guidance in selecting the right excavator thumb for your operations.