The Ultimate Guide to Finding the Best Loader Bucket for Your Tractor: Efficiency, Durability, and Value for Sale - Bonovo

Choosing the right loader bucket for your tractor or front end loader is more than just a purchase; it's an investment in your machine's productivity and your business's bottom line. Whether you're running a compact tractor on a farm or heavy equipment on a construction site, the bucket is often the most frequently used attachment. This article, written from my perspective as Allen, a manufacturer with years of experience at Bonovo, aims to demystify the process of selecting the perfect loader bucket. We'll explore different bucket types, key features to look for, and how to find quality buckets for sale that offer both performance and longevity. If you're like our typical customer, Mark Thompson from the USA, you value quality and durability but also seek competitive pricing and reliable suppliers. This guide is for you, helping you make an informed decision to enhance your loader's capabilities.

Why is Choosing the Right Loader Bucket Crucial for Your Construction or Farm Operations?

For any construction or farm operation, efficiency is king. The loader bucket you choose for your tractor or loader directly impacts how quickly and effectively you can move materials, dig, or carry out various tasks. A mismatched bucket—too large, too small, or not built for the material you're handling—can lead to increased cycle times, higher fuel consumption, and unnecessary wear and tear on your equipment. Imagine trying to move heavy rocks with a light-duty bucket; it’s not only inefficient but also risks damaging the bucket and potentially the loader itself.

Selecting the optimal loader bucket ensures your tractor loader operates at its peak. It means less strain on the machine's hydraulics and structure, leading to a longer operational life for your valuable equipment. For instance, a bucket with the correct width and capacity for your loader allows for full loads without overloading, maximizing each trip. This careful selection translates into tangible benefits: projects completed faster, reduced operational costs, and a safer working environment. At Bonovo, we've seen firsthand how the right bucket transforms a good loader into a great one, a sentiment often echoed by experienced operators like Mark.

Furthermore, the right loader bucket contributes to the versatility of your tractor or loader. A standard bucket might be great for general-purpose work, but specialized tasks might require a different design. Investing in a quality bucket that is well-suited to your primary applications ensures you get the most out of your front end loader. This isn't just about the initial purchase; it's about the long-term value and productivity the bucket brings to your daily operations, whether on a busy construction site or a demanding farm.

What Types of Loader Buckets Are Available for Different Tractors and Loaders?

The market offers a wide array of loader buckets, each designed for specific tasks and loader types. Understanding these variations is the first step to finding the perfect bucket for your needs. For general-purpose use on a farm tractor or a compact tractor loader, a standard bucket (often called a general-purpose or GP bucket) is usually the go-to option. These buckets are designed for digging, loading, and moving loose materials like soil, sand, and gravel. They offer a good balance of capacity and durability for everyday tasks.

For more demanding applications, especially in construction or when dealing with abrasive materials, heavy-duty (HD) or severe-duty (SD) buckets are available. These buckets are built with thicker steel, reinforced wear plates, and often a stronger cutting edge to withstand harsh conditions. If your loader frequently handles rocks or demolition debris, a rock bucket is essential. These are the toughest buckets, featuring robust construction, often with specialized teeth and side cutters, designed to penetrate and carry dense, heavy materials. We offer various Rock Buckets for Wheel Loaders specifically designed for these challenging jobs.

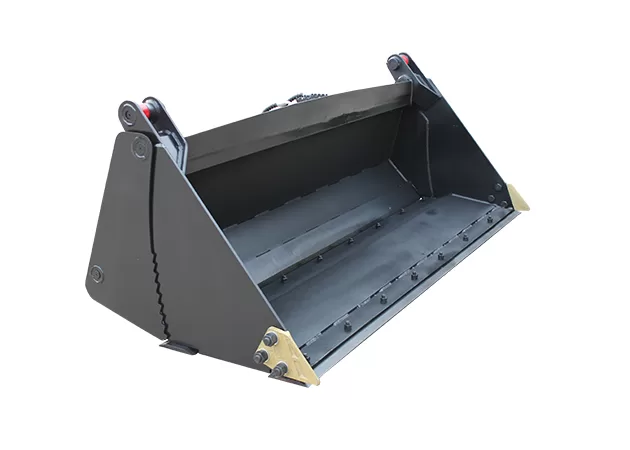

Beyond these, there are specialized loader buckets like the multi-purpose or 4-in-1 bucket, which can function as a standard bucket, grapple, dozer blade, and grader. Light material buckets are designed with a larger capacity for moving lighter, bulkier materials like snow, mulch, or grain. The type of loader you own—whether it's a large wheel loader, a versatile skid steer loader, or a compact tractor with a front end loader—will also influence the bucket options available and suitable for your equipment.

Here's a quick overview of common loader bucket types:

| Bucket Type | Primary Use | Key Features | Typical Machine Match |

|---|---|---|---|

| Standard Bucket | Soil, sand, gravel, general loading | Versatile, good all-arounder | Tractor Loader, Compact Loader |

| Heavy-Duty Bucket | Abrasive materials, moderate digging, construction | Reinforced, thicker steel, wear strips | Wheel Loaders, Backhoe Loaders |

| Rock Bucket | Quarrying, hard rock, demolition | Extreme durability, specialized teeth, thick plate | Large Wheel Loaders, Excavators |

| Light Material Bucket | Snow, mulch, grain, low-density materials | High volume capacity, lighter construction | All Loader types, Tractors |

| 4-in-1 Bucket | Dozing, grappling, loading, leveling, spreading | Multi-functional, versatile | Skid Steer Loaders, Compact Loaders |

| Grapple Bucket | Logs, brush, debris, oddly shaped items | Clamping arms, secure grip | Skid Steers, Tractor Loaders |

Understanding these distinctions will help you narrow down your choices when you shop for a new loader bucket.

How Can a High-Quality Bucket Enhance Your Compact Tractor's Performance?

A compact tractor is a versatile workhorse, especially on smaller farms, landscaping projects, or property maintenance. The performance of your compact tractor's front end loader is significantly influenced by the bucket attached to it. A high-quality bucket, properly sized and designed for the tractor's capacity, can dramatically enhance its efficiency and utility. It’s not just about moving material; it’s about doing so smoothly, without overstressing the compact tractor's hydraulics or frame.

Using a well-made loader bucket means your compact tractor can handle tasks with greater ease. For example, a bucket with a good rollback angle will retain more material, reducing spillage and the number of trips needed. A sharp, durable cutting edge on the bucket allows for easier penetration into piles or an easier scrape, requiring less power from the tractor. This translates to fuel savings and less wear on the compact tractor itself. We, as manufacturers, pay close attention to these design details to ensure our tractor buckets maximize your machine's potential.

Moreover, a high-quality bucket is built to last. Compact tractors might be smaller, but they often work hard. A bucket made from high-strength steel with good welding will withstand the daily grind far better than a cheaply made alternative. This durability means fewer replacements, less downtime, and ultimately, better value for your money. Investing in a robust loader bucket ensures that your compact tractor remains a reliable and productive piece of equipment for years to come, efficiently handling everything from moving soil to clearing snow.

When you shop for loader buckets for sale online, the sheer number of options can be overwhelming. However, knowing what to look for can help you find the best bucket for your loader or tractor. First, clearly identify your needs. What materials will you primarily be handling? What is the make and model of your loader or tractor? This information is crucial for determining the right bucket size and type. Reputable online sellers will provide detailed specifications for each bucket, including its dimensions, capacity, weight, and compatibility with different loader models.

Pay close attention to the materials used in the bucket's construction. High-tensile, wear-resistant steel (like AR400 or AR500 for wear parts) is a good indicator of a durable bucket. Look for information on the thickness of the steel in critical areas like the shell, sides, and cutting edge. The quality of a bucket is also in its construction; check for reinforced corners, wear strips on the bottom, and quality welding. Customer reviews and testimonials, if available, can provide insights into the real-world performance and durability of the bucket you're considering.

Don't just focus on the price. While it's tempting to go for the cheapest item available, a low-quality bucket can cost you more in the long run due to premature wear, breakage, and inefficient operation. Consider the overall value, which includes durability, performance, and the supplier's reputation. Ensure the supplier provides clear information about shipping, warranty, and return policies. At Bonovo, we strive to provide all necessary details for our Excavator Attachments, including our extensive range of loader buckets, to help customers like Mark make confident purchasing decisions online.

Understanding Bucket Specifications: Size, Cutting Edge, and Material Strength.

Delving into bucket specifications is essential to ensure you select a loader bucket that perfectly matches your loader's capabilities and your job requirements. The size of the bucket, usually measured in width and cubic capacity (e.g., cubic yards or meters), is a primary consideration. A bucket that's too large can overload your loader, leading to instability, reduced maneuverability, and excessive strain on the loader's arms and hydraulics. Conversely, a bucket that's too small will mean more cycles to move the same amount of material, reducing efficiency. Always refer to your loader's manual for recommended bucket size and lift capacity.

The cutting edge of the loader bucket is another critical component. This is the part of the bucket that makes first contact with the material. A sharp, durable cutting edge improves penetration, reduces the effort required by the loader, and extends the life of the bucket shell. Many buckets come with a bolt-on cutting edge, which can be easily replaced when worn. Some buckets may also have teeth or segments bolted onto the cutting edge for enhanced digging in compacted soils or rocky terrain. The material of the cutting edge itself should be hardened, wear-resistant steel for longevity.

Material strength is paramount for a loader bucket's durability. High-quality buckets are typically made from high-strength, low-alloy (HSLA) steel or quenched and tempered steels like AR (abrasion-resistant) steel in wear-prone areas. The thickness of the steel used for the bucket shell, sides, and reinforcement plates directly impacts its ability to withstand a_brasion and impact. Look for details about the grade of steel used and any additional reinforcements, such as wear bars or cheek plates on the sides of the bucket. A well-built bucket with superior material strength will provide a longer service life and better performance for your tractor loader.

The Importance of Bolt-on Cutting Edges and Other Bucket Features.

When evaluating a loader bucket, features like bolt-on cutting edges can significantly impact its long-term usability and cost-effectiveness. A bolt-on cutting edge is a replaceable wear strip that protects the leading edge of the bucket. As this edge is subjected to the most wear, having the ability to simply unbolt and replace it, rather than refurbishing or replacing the entire bucket, is a major advantage. This feature not only extends the overall life of the loader bucket but also makes maintenance easier and more affordable. You can keep your bucket performing at its best by regularly inspecting and replacing the bolt-on cutting edge as needed.

Other important features to consider in a loader bucket include wear plates or skid pads on the bottom of the bucket. These provide additional protection against abrasion, especially when working on hard surfaces or with abrasive materials. Reinforced corners and side cutters can also enhance the bucket's durability and digging performance. For specific applications, features like spill guards at the top of the bucket can help retain material during transport, increasing efficiency. The design of the bucket's back and mounting interface is also crucial for proper fitment and force distribution on your loader or tractor.

The number and placement of bolt holes for cutting edges or optional teeth should also be considered for flexibility. A standard bolt pattern makes it easier to find replacement parts. Some buckets are designed with pre-drilled holes for optional side cutters or teeth, allowing you to customize the bucket for different tasks. Investing in a loader bucket with these thoughtful features ensures that it's not just a container for material, but a well-engineered tool designed for performance, durability, and ease of use. When we design a new bucket model, these are the details we focus on to deliver a high-quality product.

Beyond the Standard Bucket: Exploring Specialized Loader Attachments.

While a standard loader bucket is a versatile tool, many operations can benefit from specialized loader attachments designed for specific tasks. These attachments can significantly expand the capabilities of your loader or tractor, turning it into a multi-functional piece of equipment. For instance, if you frequently handle logs, brush, or bulky, irregular materials, a grapple bucket is an invaluable attachment. Its clamping arms secure the load, making it much safer and more efficient to carry such items than with a standard bucket.

Another highly versatile attachment is the 4 In 1 Bucket For Skid Steer Loader, which, as its name suggests, can perform four main functions: digging/loading like a standard bucket, dozing with the clamshell open, grappling, and bottom dumping for precise material placement. This type of bucket is particularly popular for landscaping and light construction work, offering incredible flexibility from a single attachment. Other specialized buckets include rock buckets for heavy-duty excavation, light material buckets for high-volume, low-density materials, and skeleton buckets for sifting out soil from rocks.

Exploring these specialized attachments can help you maximize the return on your loader investment. While they may represent an additional upfront cost, the increased efficiency and capability they provide can lead to significant time and labor savings. As a manufacturer, we, Bonovo, offer a wide range of these specialized attachments, including various buckets and other tools like augers and pallet forks, designed to fit a variety of loader and tractor models. Consider the full scope of your work and how a specialized bucket or attachment could streamline your operations.

How Do We Make Sure Our Buckets Meet Top Quality Standards for Your Equipment?

As a factory specializing in manufacturing excavator attachments, skid steer attachments, and wheel loader attachments, including a wide variety of buckets, ensuring top quality is our utmost priority. For customers like Mark Thompson, who rely on their equipment daily, the durability and reliability of a loader bucket are non-negotiable. Our process begins with meticulous design, where we consider the stresses a bucket will endure, the types of materials it will handle, and compatibility with various loader and tractor models. We use advanced CAD software to optimize the bucket shape for efficient loading and material retention.

The next crucial step is material selection. We source high-quality, wear-resistant steel, such as NM400, NM500, or Hardox (or equivalent grades), for the main body and critical wear areas of our buckets, including the cutting edge and side plates. This choice of material significantly enhances the bucket's strength and lifespan, even in demanding construction or mining environments. Our production lines employ skilled welders and advanced robotic welding technology to ensure strong, consistent welds that can withstand the forces exerted during heavy loader operations. Every bolt hole is precisely drilled to ensure perfect fitment of bolt-on cutting edges or teeth.

Finally, each loader bucket undergoes rigorous quality control checks throughout the manufacturing process and before shipping. This includes dimensional checks, weld inspection, and verification that all specifications are met. We understand that a new bucket needs to perform flawlessly from day one. By maintaining these high standards, we aim to provide loader buckets that not only meet but exceed the expectations of our customers, ensuring their equipment operates efficiently and reliably. This commitment to quality is what makes our buckets for sale a sound investment.

Finding the Best Loader Bucket: Balancing Price, Durability, and Supplier Reliability.

Finding the best loader bucket for your tractor or loader involves more than just picking an item from a catalog; it’s about striking the right balance between price, durability, and the reliability of the supplier. While competitive pricing is important, especially for business owners like Mark who are profit-conscious, the cheapest bucket is rarely the best value. A low-cost bucket might save money upfront but could lead to higher long-term costs due to premature wear, frequent repairs, or even failure that causes costly downtime for your equipment.

Durability should be a key factor in your decision. A loader bucket made from high-strength, abrasion-resistant steel with reinforced stress points will last significantly longer and perform better than a bucket made from inferior materials. Look for features like hardened cutting edges, wear strips, and robust welding. Consider the typical lifespan of the bucket and the warranty offered by the manufacturer. Investing a bit more in a durable bucket often pays off through reduced maintenance and replacement costs, making it a more economical choice over time for your tractor loader or front end loader.

Supplier reliability is equally crucial. A good supplier, like us at Bonovo, will provide transparent information about their buckets, including detailed specifications, materials used, and compatibility. They should offer good customer service, be responsive to inquiries, and provide reliable after-sales support, including the availability of spare parts like bolt-on cutting edges or Excavator Bucket Pins. When you shop for a new loader bucket, especially online, choose a supplier with a proven track record and positive customer feedback. This ensures you not only get a quality bucket but also a partner you can trust for your equipment attachment needs.

What Are the Key Considerations When Purchasing a New Loader Bucket for Your Front End Loader or Tractor Loader?

Purchasing a new loader bucket for your front end loader or tractor loader is a significant decision that directly impacts your operational efficiency. The first key consideration is compatibility. Ensure the bucket is designed for your specific loader model, considering its lift capacity, breakout force, and mounting system. An improperly matched bucket can damage your loader or operate inefficiently. Always check the manufacturer's recommendations for bucket size and weight for your equipment.

Next, assess the primary application of the bucket. Will you be handling light materials on your farm, or heavy-duty excavation in construction? This will determine the type of bucket you need—whether it's a standard bucket, a heavy-duty bucket, a rock bucket, or a specialized attachment. Consider the materials the bucket is made from; high-strength, wear-resistant steel is essential for durability. Examine the bucket's design features, such as the shape, rollback angle, and the quality of the cutting edge. A well-designed bucket will fill more easily, retain material better, and last longer.

Finally, think about the long-term value. This includes not just the initial purchase price of the loader bucket, but also its expected lifespan, maintenance requirements (like replacing a bolt-on cutting edge), and the warranty offered. Choosing a reputable supplier who offers quality buckets for sale and stands back of their products provides peace of mind. At Bonovo, we aim to provide our customers with loader buckets that deliver exceptional performance and durability, ensuring their new attachment is a productive and lasting investment for their tractor or loader. Whether you need a bucket for a Wheel Loader DWL25 2.5 Ton or a smaller compact tractor, these considerations will help you make the right choice.

Key Takeaways for Your Next Loader Bucket Purchase:

- Match the Bucket to Your Machine: Ensure the loader bucket is compatible with your tractor or loader's size, capacity, and mounting system. An incorrect bucket can lead to inefficiency and damage.

- Consider Your Primary Application: Choose a bucket type (e.g., standard, heavy-duty, rock, light material) designed for the materials you handle and the tasks you perform most often in your construction or farm work.

- Prioritize Quality and Durability: Look for buckets made from high-strength, wear-resistant steel, with features like reinforced stress points and bolt-on cutting edges. This means a longer life for your loader bucket.

- Understand Key Specifications: Pay attention to bucket size (width and capacity), the type and material of the cutting edge, and overall bucket weight to optimize your loader's performance.

- Look for Value, Not Just Price: The best loader bucket offers a balance of fair price, robust construction, and reliable performance. A cheap bucket can be more costly in the long run.

- Choose a Reputable Supplier: Work with a supplier who provides detailed product information, good customer service, and stands behind their buckets for sale.

- Specialized Buckets for Specialized Tasks: Don't overlook specialized loader attachments like 4-in-1 buckets or grapple buckets if your work can benefit from their unique capabilities. They can significantly enhance the versatility of your front end loader or tractor loader.