- Home> Products > Undercarriage > Others

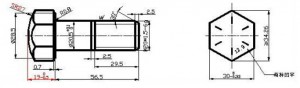

BONOVO Undercarriage Parts Excavator Bulldozer Track Bolts And Nuts

Bonovo supplies a variety of Track Shoe Bolts & Nuts in both inch and metric sizes, these black track bolts and nuts is specially for cutting edge used in popular models.

In order to achieve a more perfect fit, Bonovo can customize the size according to the needs of customers.

Features/Advantages

1). Materials:

Our company We use high quality steel, have good mechanical properties and stability of chemical component. it keep the bolt to be of high strength

2). Manufacture Procession

First, we have our own High-precision Digital Machining center for mould making in special Mould Workshop, excellent mould make product beautiful appearance and its size accurately.

The second, we adopt blasting procession, removing Oxidation surface , make the surface to be bright and clean and uniform and beautiful.

The third, in heat treatment: We use the Controlled-atmosphere Automatic heat treatment Furnace, we also have four mesh belt convey furnaces, Can deal with the products in different sizes keeping the non-oxidation surface

3). The all process quality control:

The quality control is strictly performed from buying raw materials in warehouse to different machining procession and to final packing. We have Magnetic Powder Detector, Material Testing Machine, Metallographic Microscope, such testing instruments, guarantee product high quality and beautiful appearance.

| Specification | Model | |

| TRACK BOLT-3/4x61mm | TB3/4*2.13/32B | 7H3598 |

| TRACK NUT-3/4 | TB3/4NS | 1S1860 |

| TRACK BOLT-M18X 59mm | TB18*59B | 79004259 |

| TRACK NUT-M18 | TB18NS | 79009445 |

| TRACK BOLT l”X90MM(D9N) | TBT3.35/64B | 6T2638 |

| TRACK NUT 1" (D9N) | TB1NU | 7G0343 |

| TRACK BOLT 5/8"X53MM | TB5/8*2.5/32B | 9G3110 |

| TRACK NUT 5/8" | TB5/8NS | 1M1408 |

| TRACK BOLT M20X63MM | TB20*63WB | 6Y0846 |

| TRACK NUT M20 | TB20NS | 9W3361 |

| TRACK BOLT M20X56MM | TB20*56WB | 20Y-32-1121A |

| TRACK NUT M20 | TB20NS | 20Y-32-16 |

| TRACK BOLT M22X73MM (330 Exc) | TB22*73B | 8E6103 |

| TRACK NUT M22 (330 Exc) | TB22NS | 9W4381 |

| TRACK BOLT M24X75MM(D155) | TB24*75B | 176-32-11210 |

| TRACK NUT M24(D155) | TB24NS | 176-32-11220 |

| TRACK BOLT M30X96(D375-2/3) | TB30*96B | 195-32-61210 |

| TRACK NUT M30 (D375-2/3) | TB30NU | 195-32-61221 |

| TRACK BOLT 7/8" X 85MM D8N/R/L | TB7/8*3.1V32B | 7T2748 |

| TRACK NUT 7/8" D8N/R/L | TB7/8NU | 7G6442 |

| Segment Bolt (M22x 1.5 x 71mm) D65/D85 | SM22*70B(D85) | 155-27-12181 |

| Nut - Hex (M22x 1.5) D65/D85 | SM22NH | 01803-02228 |

| TRACK BOLT M27 X90MM C375 | TB27*90B | 6Y7432 |

| TRACK NUT M27 | TB27NU | 6Y7433 |

Testing

production process

Production procedures

Production Procedures

Production Procedures