BONOVO Undercarriage Parts Track Adjuster Assy Track Tensioner

Track adjuster or tensioner also called track adjuster cylinder which is used onto excavators and bulldozers.

Available for all brands and models of excavators, Hitachi, Komatsu, Caterpillar and other types of excavator crawler regulators.

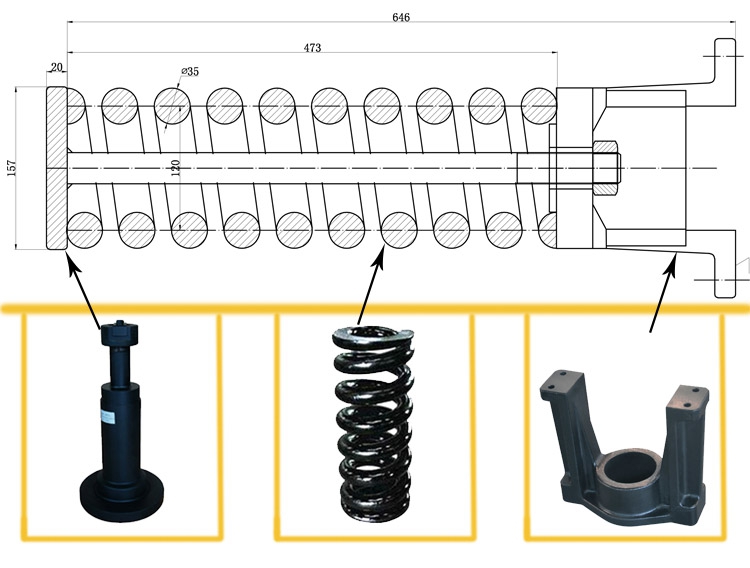

A track adjuster assembly consists of a recoil spring, cylinder and a yoke.

Features

Tensioner for construction machine also could be called Recoil Spring Assembly.

It is consist of hydraulic system, recoil spring and connection parts.

Exclusive seal group ensure no oil leakaging, providing a stable status of hydraulic system for any working conditions.

The application of automatic in furnace roll-over device in roller hearth electric furnace can make the burning of material well-proportioned, as a result the finished spring performs more stable.

Specification

| Material | 60Si2MnA,60Si2CrA,60Si2CrVA |

| Wire diameter | 5mm~80mm |

| Free hight | 10mm~1188mm |

| hardness | 45HRC~55HRC |

| Direction of coils | Right, left |

| No.of coils | Unlimited |

| Application | Excavator, digger machine,car,train,shakeout machine,etc. |

| Color | Blackwhite,blue,red,yellow,grey,etc. |

| Production method | Hot formed.cold formed |

| Note | The materials and specifications can be dedided by the customers. |

Popular Models

- For Komatsu: PC55、PC60、PC120、PC130、PC200-6、PC200-7、PC220-6、PC220-7、PC300-6、PC300-7、PC400、D31PX-21

- For Hitachi: ZX120、ZX200、ZX200-3

- For Kobelco: SK120-3、SK200

- For Caterpillar: CAT320D

- For YANMAR: B15

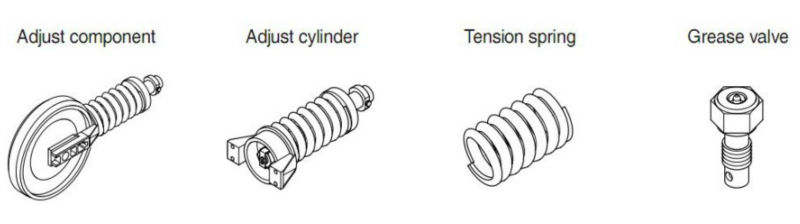

Components

a complete track adjuster assembly/spring recoil assy, or someone call it idler adjuster consisting of those components as following

Details

Testing

We use strict quality standard and follow strict SOP to proceed quality inspection

Check Your Track Tension Regularly

Operate the machine for at least a half hour to allow the track to acclimate to the working area before you check and set the track tension. If conditions change, like additional rainfall, readjust the tension. Tension should always be adjusted in the working area. Loose tension causes whipping at higher speeds, resulting in excessive bushing and sprocket wear. If the track is too tight, it causes stress on the undercarriage and drive train components while wasting horsepower.

Incorrect track tension may lead to increased wear, so it is important to adhere to the proper tension. As a general rule, when your operators are working in soft, muddy conditions, it is recommended to run the tracks slightly looser.

"If steel tracks are too tight or too loose, it can quickly accelerate wear,” “A loose track could cause the tracks to de-track."